Keywords: UHMWPE Sheet, UHMWPE Profiles, HDPE Sheet, HDPE Profiles

+86 131 7333 7240

Keywords: UHMWPE Sheet, UHMWPE Profiles, HDPE Sheet, HDPE Profiles

+86 131 7333 7240

Xinxing manufactures a range of polyurethane screens that are lighter,more cost-effective and ahieve a longer working life than standard screen panels even in harsh operating conditions.

Polyurethane tailings dewatering sieve plate, also known as tailings dry drain sieve plate, is mainly used in coal mine, iron ore, copper ore and gold ore tailings dry drain, concentrate dehydration, coal slime dehydration, debris removal, carbon slurry separation and other industries.

Description

Polyurethane Screens made from Polyurethane elastomerare are longer lasting and reduce noise and are self-cleaning. Their modular layout and conical openings prevent the screen from clogging and they are very suitable for wet sorting and dewatering

These types of polyurethane screens are the best solution for mining, sand and gravel screening, compost/wood chip processing and aggregate-ore processing as they offer a similar open area ratio of woven wire screens but the polyurethane screens coating means that they last up to five times longer than steel meshes.

Xinxing's expertise in high-tensile polyurethane screens has resulted in extensive range of products designed to suit your partcular screening requirements.

Polyurethane Screens are used for the separation of Sand, Gravel, Granite, Quartzite, Limestone and Coal to name a few of the many applications with the added advantages of:

Corrosion Proof

Reduced wear and tear

Self-cleaning

Reduced noise

Reduced breakage

Installation Type:

Flat Bolt, Pin&Leg, Pressing Bar, Rail Support.

Common Specifications:

Length:305mm,610mm...

Width:305mm,610mm...

Thickness:30mm,45mm,50mm...

Opening size:From 0.1*12mm to 4*12mm

Type: Polyurethane Sieve Plate

Material Classification Grading: 0.1-80mm

Hole Shape: comb teeth, square hole, long hole, round hole and slit type

Application: mining, metallurgy, coal, coke, coal washing, petroleum, chemical and other industries shaker washing and grading operations, etc.

1. Surveying sieve should pay attention to the first to understand the installation of the screen plate fixed, the use of the scene, and then mapping the basic parameters of the sieve plate.

2. The basic parameters of the sieve plate: mesh size, sieve in the form of sieve surface, length x width x height, fixed hole size and location.

3. According to the installation of fixed ways can be divided into the following categories: Gourd hole type, T-shaped bolt type, external compression type, tension type (hook plate), on the hanging type, under the type, oblique compression type, pressure wood (board) rail seat type.

Main Properties:

1, wear-resisting performance prolongs the service life.

2, maintenance workload is small, the polyurethane sieve plate is not easy to damage, thus greatly reduce the amount of maintenance and maintenance shutdown loss.

3, moisture resistant performance is good, can work in the water medium conditions, and in the water, oil and other media, to reduce the friction coefficient of polyurethane and material, more conducive to screening, improve screening efficiency, and can avoid the adhesion of wet particles, at the same time because the friction coefficient decreased, wear reduced, service life to improve.

4, corrosion resistance, non flammable, non-toxic and tasteless.

5, because the mesh design is reasonable, the sieve plate manufacturing process is unique, does not limit the size of the particles block the mesh.

6, the vibration absorption performance is good, the noise elimination ability is strong, can reduce the noise, and can make the sieve material in the process of vibration is not easy to break.

7, because the two vibration characteristics of polyurethane, polyurethane sieve plate has self-cleaning effect, so the screening efficiency is high.

8, energy saving, polyurethane small proportion, than the same size steel sieve weight is much lighter, so as to reduce the machine load, saving power consumption, and prolong the life time of the screen machine.

Size

Length:305mm,610mm...

Width:305mm,610mm...

Thickness:30mm,45mm,50mm...

Opening size:From 0.1*12mm to 4*12mm

Color

yellow, red, green

Applications

Steel plants.

Mining industry.

Cement plants.

Mineral beneficiation industry.

Power plants.

Coal washing.

Sand, gravel separating and screening.

Using polyurethane screen mesh can reduce the weight too much and also reduce the cost. It has long serving life and low noisy, widely used in mine, metallurgy, coal, coke, coal, coal washing, oil, chemical industry.

Medical: compression dressings, pressure infuser bags, ergonomic hand held, transdermal patches, orthodontic bands, shoe insoles, tubing

Industrial: drive belts, hoses, rollers, bellows Consumer: Sports equipment, keyboard covers, rotation devices, headphone ear cushions, buoyancy compensators, packaging

Vibrating screens in coal washing plant, coking plant, mines, power plants, metallurgy, petroleum, petrochemical etc.

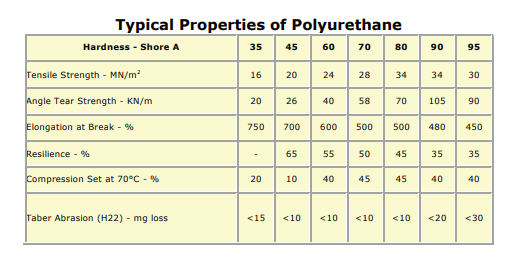

Data Sheet

Navigation

Mob.: +86 131 7333 7240

Phone: +86 534 5222 377

Fax: +86 534 7074 626

E-mail: [email protected]

Sype: sdxxhg518

WhatsApp: +86 131 7333 7240

Address: Liaohe Road, Ningjin Industry Zone, Dezhou City, Shandong, China

Follow Us