Keywords: UHMWPE Sheet, UHMWPE Profiles, HDPE Sheet, HDPE Profiles

+86 131 7333 7240

Keywords: UHMWPE Sheet, UHMWPE Profiles, HDPE Sheet, HDPE Profiles

+86 131 7333 7240

1.Polyurethane Sieve Panel as Mining PU Sieve Plate for Vibrating Screen is a kind of polymer elastic sieve, it has excellent wear resistance, oil resistance, hydrolysis resistance, bacteria, anti-aging properties.

2.Polyurethane Sieve Panel as Mining PU Sieve Plate for Vibrating Screen Widely used in the mining, metallurgy, coal, coke, coal washing, petroleum, chemical and other industries shaker washing and grading operations.

3.Polyurethane Sieve Panel as Mining PU Sieve Plate for Vibrating Screen hole shape: comb teeth, square hole, long hole, round hole and slit type.

4. Material classification grading: 0.1-80mm.

Description

(1) Polyurethane Sieve Panel as Mining PU Sieve Plate for Vibrating Screen Features:

1.Good wear resistance, long service life, wear resistance of steel sieve plate 3-5 times for the ordinary rubber sieve plate more than 5 times.

2.Maintenance workload is small, difficult to damage the polyurethane sieve plate, long service life, it can greatly reduce maintenance and shutdown maintenance loss.

3.Low cost, polyurethane sieve plate life is 3-5 times the stainless steel sieve, maintenance and replacement of small number of more practical.

4.Good moisture resistance, in the case of water, oil and other media, polyurethane and the material of the friction coefficient is lower, more conducive to through the screen to improve the screening efficiency, and to avoid adhesion of wet particles, long service life.

5.Corrosion-resistant, non-flammable, non-toxic and tasteless.

6.Sieve manufacturing process unique, particles will not block the sieve.

7.Vibration absorption performance, strong muffler, can reduce noise, vibration in the sieve process is not easy to break.

8.Due to the secondary vibration characteristics of polyurethane, polyurethane sieve plate with self-cleaning effect, so high screening efficiency.

9.Energy saving, small proportion of polyurethane, reducing the screen machine load, and extend the life of screening machine.

(2)

Type of Polyurethane Sieve Panel as Mining PU Sieve Plate for Vibrating Screen:

1.Polyurethane cantilever grizzly sieve plate, through special process equipment, elastic polyurethane composite polymer on the bars, has the advantages of abrasion resistance and corrosion resistance, anti aging, suitable for wear serious vibration sieve, mainly used for the high wear resistance of the coke industry, the classification of grain size is generally more than 16mm.

2.Ceramic polyurethane grizzly sieve plate is a new product developed by our company, is through the special adhesive bonding in polyurethane bar on high wear-resistant ceramic sheet. Sieve plate with impact resistance, wear-resistant. Mainly used for the better wear resistance of coke screening, the classification of grain size is generally more than 16mm.

(3)

Polyurethane Sieve Panel as Mining PU Sieve Plate for Vibrating Screen Application:

Polyurethane Sieve Panel as Mining PU Sieve Plate for Vibrating Screen widely used in metallurgy, coke, coal, mining and other industries, mainly for the screening of the more stringent requirements of the sintering mine.

(4)

Mapping elements of the sieve plate:

1. Surveying sieve should pay attention to the first to understand the installation of the screen plate fixed, the use of the scene, and then mapping the basic parameters of the sieve plate.

2. The basic parameters of the sieve plate: mesh size, sieve in the form of sieve surface, length x width x height, fixed hole size and location.

3. According to the installation of fixed ways can be divided into the following categories: Gourd hole type, T-shaped bolt type, external compression type, tension type (hook plate), on the hanging type, under the type, oblique compression type, pressure wood (board) rail seat type.

(5)

In recent years, a large number of products exported to countries around the world, mainly enjoy a high popularity and reputation, is the world's largest green steel material sorting system and thermal power generation coal handling system screening equipment suppliers.

Products are widely used in India Mittal, Tata Steel and other iron and steel enterprises, China Coal International, Vale of Brazil and other coal mining enterprises, Turkey SILOPI power plant, India BALCO power plant and other power companies.

Size

Material: polyurethane material and embedded steel frame.

Thickness: 30mm - 60mm.

Aperture type: square, rectangular and round.

Aperture size: 5mm - 50mm.

Connection type: mosaic connection, bolts connection, press bar connection and hook connection.

Color

red, yellow, green

Applications

Steel plants.

Mining industry.

Cement plants.

Mineral beneficiation industry.

Power plants.

Coal washing.

Sand, gravel separating and screening.

Using polyurethane screen mesh can reduce the weight too much and also reduce the cost. It has long serving life and low noisy, widely used in mine, metallurgy, coal, coke, coal, coal washing, oil, chemical industry.

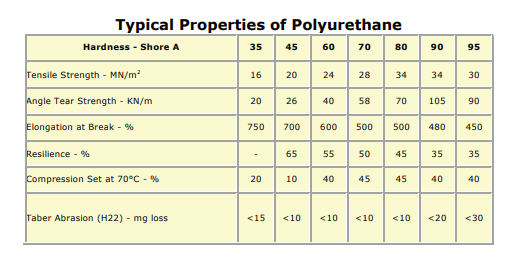

Data Sheet

Navigation

Mob.: +86 131 7333 7240

Phone: +86 534 5222 377

Fax: +86 534 7074 626

E-mail: [email protected]

Sype: sdxxhg518

WhatsApp: +86 131 7333 7240

Address: Liaohe Road, Ningjin Industry Zone, Dezhou City, Shandong, China

Follow Us