Keywords: UHMWPE Sheet, UHMWPE Profiles, HDPE Sheet, HDPE Profiles

+86 131 7333 7240

Keywords: UHMWPE Sheet, UHMWPE Profiles, HDPE Sheet, HDPE Profiles

+86 131 7333 7240

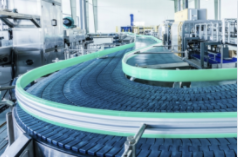

uhmwpe wear strip for material handling equipments

Material handling processes often utilize machinery with many moving parts. After time, the points of contact between moving parts can wear down and cause disruptions in the workflow. Wear strips and components act as a sacrificial link in the system to prevent damage to the critical components of the equipment.

Wear strips and components are often made of plastic, which provides protection from surface marring and scratching, noise reduction between mating parts, and elimination of slipping and sticking amid sliding parts. One of the most common plastic materials used in wear strip applications is UHMW (Ultra High Molecular Weight Polyethylene). UHMW’s unique properties including high impact/abrasion resistance, self-lubrication, long wear life and ease of machining make it ideal for this application. Wear strips and components are resistant to corrosion and chemicals and able to keep moving parts free of external grease and lubricants. Wear strips and components are commonly used with bearings, slides, gears, cams, bushings, and rollers.

Xinxing Plastics stocks a large variety of materials for wear strips and components, including UHMW in a wide variety of thicknesses and sheet sizes. The team at Xinxing is knowledgeable in all of our product offerings and can help you choose the best materials for your project. For more challenging applications where the standard materials just won't do, our team of experts will work closely with you to find the best solutions.

Description

UHMWPE material wear strip has exceptionally low coefficient of friction offering superb sliding properties and is one of the best plastics for wear/abrasion resistance meanwhile tough and impact resistant even at cryogenic temperatures. As a result, it is definite that UHMW polyethylene is a wonderful engineering plastic that can solve many problems that other engineering plastics cannot.

1. Doesn't wear easily

Having an incredibly high molecular weight,Virgin UHMW Ultra high molecular weight Drag conveyor - U type Uhmwpe Drag Flight proves its true worth not only in regards to sliding with metal faces, but also sand, powder and other fields where normal wear-resistant materials struggle.

2. Excellent sliding ability

Virgin UHMW Ultra high molecular weight Drag conveyor - U type Uhmwpe Drag Flight has an extremely low friction coefficient. It is comparable to PTFE, which also slides well.

3. Doesn't crack easily

Virgin UHMW Ultra high molecular weight Drag conveyor - U type Uhmwpe Drag Flight has a level of shock resistance simply not found in other materials. Does not break easily unless affected chemically.

4. Non-adhesive

Highly non-adhesive. With a non-adhesiveness second only to PTFE, Virgin UHMW Ultra high molecular weight Drag conveyor - U type Uhmwpe Drag Flight is optimal as a material for the inner liners of containers such as hoppers, silos and chutes.

5. Non-toxic and safe

A physically non-toxic material. Great for use with food products, Virgin UHMW Ultra high molecular weight Drag conveyor - U type Uhmwpe Drag Flight can also be used in the medical field.

6. Difficult to penetrate

Virgin UHMW Ultra high molecular weight Drag conveyor - U type Uhmwpe Drag Flight Features excellent chemical resistance.

7. Doesn't absorb water.

Virgin UHMW Ultra high molecular weight Drag conveyor - U type Uhmwpe Drag Flight has an absorption rate of virtually zero, therefore its strength does not deteriorate due to swelling caused by water absorption.

UHMWPE advantages:

1. wear resistance

2. impact resistance

3. corrosive resistance

4. low temperature resistance

UHMWPE wear strip is cut from UHMWPE sheet semis. Usually for UHMWPE application, customers will need only some strips instead of sheets or slabs or so by demands, Xinxing Ultrahigh will glad to cut UHMWPE sheet/slab semis into strips as well as the UHMWPE semis production such as sheets, blocks, strips, slabs and rods etc.

Whether for usage of UHMWPE machining or lining system or some other occasions, it is just the UHMWPE properties that attract all customers to utilize UHMWPE material.

Some characteristics of UHMW polyethylene have been listed as following:

1. High abrasion resistance - 7 times outwearing carbon steel, long life-span.

2. Low coefficient of friction - self-lubricating.

3. Low moisture absorption - non-caked.

4. High impact strength - comprehensive mechanical properties.

5. High resistant to corrosive chemicals - no ageing.

6. Low temperature resistance

7. Non-toxic.

8. Electrical insulating.

9. Lightweight - 1/8 the weight of carbon steel.

UHMWPE Applications:

Best material as liners for bulk storage and transportation equipments, for instance hoppers and chutes etc. UHMWPE strips are widely applied to power plants, steel companies, mine and machinery areas, granaries, glass industries, self-unloading ships and so on.

Also, to be machined into wear parts/components, such as conveyor guide rails, belt scrapers, chain guides and suspension wear plates etc., UHMWPE strips can be machined into various types to get special purposes in a variety of industries even food & beverage lines.

Size

3000x70x15mm, 3000x150x15mm, 4000x50x12mm, 4000x100x15mm

Color

white, black, yellow, blue, green, grey, orange, red

Applications

Our UHMWPE wear strips can be widely used for long-term maintenance-free purposes. This UHMWPE profile can be applied to office equipment, textile machinery, pneumatic components, fitness equipment, printing machinery, micro-motors, automobiles, agricultural machinery, cement grout pumps, port machinery, and other applications that require corrosion-resistant sliding parts.

Navigation

Mob.: +86 131 7333 7240

Phone: +86 534 5222 377

Fax: +86 534 7074 626

E-mail: [email protected]

Sype: sdxxhg518

WhatsApp: +86 131 7333 7240

Address: Liaohe Road, Ningjin Industry Zone, Dezhou City, Shandong, China

Follow Us