Keywords: UHMWPE Sheet, UHMWPE Profiles, HDPE Sheet, HDPE Profiles

+86 131 7333 7240

Keywords: UHMWPE Sheet, UHMWPE Profiles, HDPE Sheet, HDPE Profiles

+86 131 7333 7240

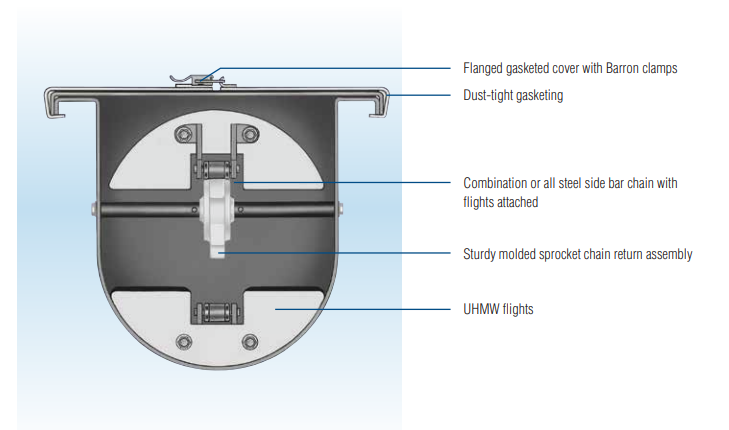

Advatages of UHMWPE drag flights and drag conveyor flights

1. UHMW exhibits virtually no water absorption

2. Non-Toxic

3. Low coefficient of friction

4. Corrosion resistant

5. Abrasion and impact resistant

6. Wear Resistant

7. Dielectric

8. Weatherproof

Description

Drag conveyors are ideal for transporting homogenous, bulk material, but they vary widely in terms of quality. Many drag systems still resemble models from the 1800s, when they were first invented, while others showcase developments that have made these machines more reliable and more profitable. Understanding these developments will help you identify material handling solutions that will enable your plant to operate more smoothly and profitably and avoid out-of-date machinery.

In the 20th century, engineers added paddles to the flights. Paddles allowed drag conveyors to move larger loads at steeper inclines. They also provided a fail point if an obstruction occurred. With a flight-only design, if the flight failed, the next thing in line to break was the chain or sprocket. By using paddles, maintenance crews had something to observe before the flights broke—the paddles would bend backwards when they met an obstruction. If checked regularly by maintenance crews, personnel could thus identify an obstruction before it got worse.

Friction and Wear

Inefficiencies in the traditional drag chain design largely stem from internal friction and wear. In the standard design, the chain drags the paddles over the bottom panels of the conveyor. While doing such, the chain and paddles rub the floor panels and sidewalls. Energy that should move material is therefore used to overcome this resistance. The rubbing also wears the panels, the chains, and the paddles. As a result, personnel must commonly replace the panels whenever the chain needs replaced, and the paddles become less efficient over time.

Recent Advancements in Drag Conveyor Design

While many drag conveyors still employ a single-chain design, and while the overall scheme of a drag conveyor wasn’t revolutionized in the 20th century, there have been a few manufacturers who have made smart advances in drag conveyor technology in recent years. Major changes include:

* Running the chains in troughs outside the material path

* Running the chains on UHMW wear strips

* Keeping the paddles off the floor and sidewall panels

* Shaping the paddles to pack coarse material without it wedging under the paddles

By running the chains in troughs outside the material path, the chains are spared some of the acidic and mechanical wear that comes from contact with material. It also reduces the amount of material that collects in the chain and gets wrapped around the sprockets. It furthermore keeps the chains off the bottom panels, where they will wear through them. Another advantage to this design is that it better keeps the paddles from twisting if they’re loaded unevenly: in a channel, there is little room for the chains to twist.

Running the chains on UHMW wear strips reduces the amount of friction inside the conveyor. It also reduces maintenance costs. It costs much less to replace a UHMW or nylon wear strip than it does a steel panel—not that replacing these wear components in modern drag conveyor is difficult or something that occurs frequently. Wear strips in straight sections incur little wear, as the forces in the chains are primarily horizontal. When they do need replaced, the best systems allow you to do so with the chains under tension. Curve wear strips in these systems can be replaced from outside the conveyor without opening any panels, which decreases downtime.

Size

made to order

we can CNC machine and finish uhmwpe drag flights and drag conveyor flights

Color

white

Applications

conveyor machinery

conveyor equipments

materials handling equipments

coal mining industry

Navigation

Mob.: +86 131 7333 7240

Phone: +86 534 5222 377

Fax: +86 534 7074 626

E-mail: [email protected]

Sype: sdxxhg518

WhatsApp: +86 131 7333 7240

Address: Liaohe Road, Ningjin Industry Zone, Dezhou City, Shandong, China

Follow Us