Keywords: UHMWPE Sheet, UHMWPE Profiles, HDPE Sheet, HDPE Profiles

+86 131 7333 7240

Keywords: UHMWPE Sheet, UHMWPE Profiles, HDPE Sheet, HDPE Profiles

+86 131 7333 7240

Polyurethane sieve plate is a kind of polyurethane as raw material to produce the mesh products

The hole shape of sieve plate: Sewing, rectangle, circle, square

Main application industry :Coal washer, coking plant, mines, power plants, dredging company, metallurgy, petroleum, petrochemical, and other enterprises.

Main application equipment: Vibrating screen

The main performance and features:

1, Wear-resisting performance is good, service life is long, its wear resistance is 3 ~ 5 times that of steel sieve plate for 5 times more than ordinary rubber sieve plate.

2, Small maintenance workload, polyurethane sieve plate is not easy to damage, long service life, thus can greatly reduce the amount of maintenance and shutdown overhaul loss.

3,Low cost, although the same specification (size) of the polyurethane sieve plate is higher than stainless steel sieve plate one-time investment (about 2 times), but because of the polyurethane sieve plate life expectancy is 3 ~ 5 times long than the size of the stainless steel sieve plate, and fewer maintenance and replacement, so the total cost is not high, the economy is also very economical.

4, Moisture resistance performance is good,It can work under the condition of water as medium, and in the case of medium such as water, oil, the friction coefficient between polyurethane and material is reduced, more conducive to sieve, improve screening efficiency, and can avoid damp particle adhesion, at the same time due to lower friction coefficient, wear reduction, improve the service life.

5,Corrosion resistant, non-flammable, non-toxic tasteless.

Description

Polyurethane sieve plate is manufactured from specially formulated polyurethane and high tensile embedded steel frame. Combined with wear resistance urethane and high tensile strength steel frame, modular polyurethane screen mesh possesses excellent performance in separating and screening industry.

Similar as polyurethane dewatering screen, modular polyurethane screen also has various connection types, including the bolts connection type, mosaic connection type, press bar connection type and hook connection type. Various connection types can fit different machines and different applications. It is the most versatile and cost effective modular system.

Specifications:

Material: polyurethane material and embedded steel frame.

Thickness: 30mm - 60mm.

Aperture type: square, rectangular and round.

Aperture size: 5mm - 50mm.

Connection type: mosaic connection, bolts connection, press bar connection and hook connection.

Applications:

The modular polyurethane screen mesh can fit various vibrating screens and widely used in various applications.

Steel plants.

Mining industry.

Cement plants.

Mineral beneficiation industry.

Power plants.

Coal washing.

Sand, gravel separating and screening.

Features:

Polyurethane materials for wear resistance.

Self-cleaning apertures reducing pegging and blinding.

Wide range apertures suit most applications.

Various panel sizes to suit all vibrating screens.

Different connection type for easy installation and replacement.

High screening performance.

Low noise.

Long service life and durable

Benefits

Abrasion resistant

Oil and solvent resistant

Long service life

Tear strength

Resistance to weathering

Noise reduction

Flexibility

Applications

Medical: compression dressings, pressure infuser bags, ergonomic hand held, transdermal patches, orthodontic bands, shoe insoles, tubing Industrial: drive belts, hoses, rollers, bellows Consumer: Sports equipment, keyboard covers, otation devices, headphone ear cushions, buoyancy compensators, packaging

Size

Material: polyurethane material and embedded steel frame.

Thickness: 30mm - 60mm.

Aperture type: square, rectangular and round.

Aperture size: 5mm - 50mm.

Connection type: mosaic connection, bolts connection, press bar connection and hook connection.

Classing grain size: 2,3,4,5,8,10,12,15,18,20,25,30,50,75,90,120,150mm

Color

red, yellow, green

Applications

Steel plants.

Mining industry.

Cement plants.

Mineral beneficiation industry.

Power plants.

Coal washing.

Sand, gravel separating and screening.

Using polyurethane screen mesh can reduce the weight too much and also reduce the cost. It has long serving life and low noisy, widely used in mine, metallurgy, coal, coke, coal, coal washing, oil, chemical industry.

Medical: compression dressings, pressure infuser bags, ergonomic hand held, transdermal patches, orthodontic bands, shoe insoles, tubing

Industrial: drive belts, hoses, rollers, bellows Consumer: Sports equipment, keyboard covers, rotation devices, headphone ear cushions, buoyancy compensators, packaging

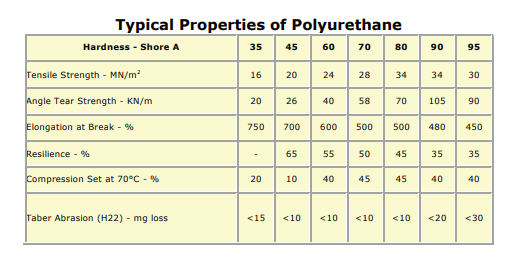

Data Sheet

Navigation

Mob.: +86 131 7333 7240

Phone: +86 534 5222 377

Fax: +86 534 7074 626

E-mail: [email protected]

Sype: sdxxhg518

WhatsApp: +86 131 7333 7240

Address: Liaohe Road, Ningjin Industry Zone, Dezhou City, Shandong, China

Follow Us