Keywords: UHMWPE Sheet, UHMWPE Profiles, HDPE Sheet, HDPE Profiles

+86 131 7333 7240

Keywords: UHMWPE Sheet, UHMWPE Profiles, HDPE Sheet, HDPE Profiles

+86 131 7333 7240

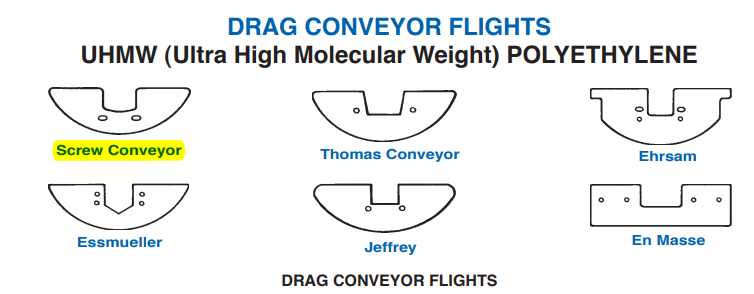

uhmwpe flights and paddles

UHMW-PE is used in a large variety of industries for many applications to solve the day to day problems incurred during operation. Undoubtedly, there are many other applications and industries other than those cited.

Description

Shipping, Handling, & Storing Industry

Wet or frozen material can be difficult to move. UHMW-PE prevents wet or frozen material from sticking to equipment. Moisture causes many materials to stick to steel, but with this type of material they move easily, without hang up. Your rail fleet will operate better with maintenance parts of UHMW which resist abrasive and corrosive dust environments. Conveyor belt return rollers do not build up with wet or frozen product when they are sleeved with UHMW. Both wet and dry materials discharge faster and more easily from storage equipment lined with UHMW.

Aggregate – Sand & Gravel Industry

The prime advantage afforded by UHMW-PE in handling aggregate and sand is that it facilitates the flow of smooth and fine aggregate and wet sand, which would normally stick to metal surfaces. In addition, UHMW will reduce or eliminate corrosion and equipment wear.

Farm Machinery Industry

Because it is often stored outdoors and exposed to the weather, agricultural machinery benefits from self-lubricating, long-lasting parts that do not corrode or freeze, even on rusty shafts and ways. Non-corrosive, non-stick characteristics make UHMW-PE ideal for contact with seed, feed, fertilizers, and wet harvest products.

Solid Waste Handling Industry

Solid waste is often corrosive and very abrasive, especially if it contains corrosive chemicals, glass, and metal scrap. In a solid waste handling system, moisture is often present, making movement of the material difficult. UHMW-PE allows the wet waste to slide more easily without sticking. It is more resistant than stainless steel to corrosion from a variety of strong chemicals and its abrasion resistance gives excellent service life. Trucks, trailers, hoppers, and bin liners with parts made of this type of material unload quietly.

Ore & Mineral Mining Industry

For direct mining, both surface and underground processing operations, UHMW-PE increases productivity by reducing sticking, holdup, and bridging. Its lubricity speeds product flow and movement. Underground mechanical operations are quieted with UHMW on areas subject to rubbing and impact. Surfaces lined with it require no lubrication and are virtually unaffected by dust and dirt buildup. UHMW-PE also lessens energy requirements and deadens noise.

Drag bucket liners easily release product and overburden in wet or freezing conditions, and this results in higher bucket output and lower energy costs. Slurry pump parts and pipe liners made of UHMW-PE reduce wear on parts and pipes, increase flow, and cut energy requirements.

Food & Beverage Handling Industry

Food and Beverage equipment parts are made of UHMW-PE because of its outstanding abrasion and impact resistance. Use of UHMW-PE increases the life of handling equipment and also contributes significantly to clean low-maintenance, low-energy, low-cost operations. UHMW-PE has a non-stick surface and parts are self-lubricating, requiring no containment grease or oil.

In addition, they are unaffected by steam cleaning, even when harsh detergents are used. For indoor operations, parts made with UHMW-PE provide the added benefit of reduced noise levels. UHMW-PE meets FDA requirements and is accepted by the USDA for poultry and meat contact.

Packaging Machinery Industry

Tobacco, cosmetic, pharmaceutical, and drug packaging machines operate cleanly and without contamination from product residue, lubricants, rust or corrosion when they are made with UHMW-PE. Moving parts need no lubricants; guide parts slide easily without staining or sticking; drive parts outwear those made of stainless steel and cost less; and cleaning with live steam and strong detergents causes no problems. Parts made with UHMW-PE are safe and sanitary and have FDA clearance and USDA acceptance for food contact.

Aeration, Chemical, & Biological Treatment Industry

UHMW-PE, the most abrasion resistant plastic, is resistant to a wide variety of harsh, chemically corrosive environments such as 80 sulfuric acid, 37% hydrochloric acid, concentrated caustic soda (sodium hydroxide) and concentrated Clorox bleach (sodium hypochlorite). In addition, UHMW-PE has outstanding environment stress-crack resistance. Combine these good corrosion-resistant properties with the low friction, self-lubricating properties of UHMW-PE and it is obvious that this plastic should be used in waste-water, chemical, and biological treatment equipment.

Forestry Industry

UHMW-PE’s low friction, high resistance to abrasion and exceptional toughness make it a good choice for wear and material flow applications in the sawmill and wood industries. Logs can cause significant wear on conveying equipment and chains & flights can wear out quickly. Holes can also develop in steel pans and chutes. UHMW-PE, which outlasts AR steel in most applications, can extend the life of conveying equipment. In addition, UHMW-PE offers sound abatement benefits, where it can reduce the noise of a dragging chain by 20 decibels.

Coal Shipping, Storage, Machinery, Mining, & Preparation

Wet or frozen coal is difficult to handle and ship. UHMW-PE liners keep it from sticking. Antifreeze can make wet coal hard to handle, but UHMW-PE liners prevent handling problems. Conveyor buckets, bin chutes, and rail-cars lined with UHMW-PE make coal handling more efficient by providing easy release, reducing corrosion and wear, and lowering labor and maintenance costs. In cold weather, wet coal will not cake on the surface of return conveyor belt rollers lined with UHMW-PE.

UHMW-PE can improve machinery life by reducing wear and corrosion. Whenever metal rubs against metal there is noise, friction, and wear. The use of UHMW-PE wear pads will eliminate noise and reduce wear and friction. When two metal surfaces impact, there is noise and potential failure. UHMW-PE pads can take the impact and eliminate noise and metal fatigue. Chains running on wear plates of UHMW-PE do not require lubrication, the plate does not wear or squeak, and the chain does not wear out.

For direct mining operations, whether surface or underground, the use of UHMW-PE will increase productivity by preventing sticking and bridges by speeding movement and flow and by reducing noise and machinery downtime. Machinery maintenance can be reduced by eliminating lubrication requirements. Energy saving can be provided by reducing friction and thermal losses. Slurry pumping can be improved with pipe liners of UHMW-PE to resist wear and reduce pumping, energy, and noise.

UHMW-PE can provide lower coal preparation costs by reducing sticking and bridging, even with fine wet coal. Liners for processing tanks will reduce corrosion, wear, and sticking. Screening, conveying, and handling operations can be made quieter and more energy-efficient by reducing friction and thermal losses. Slurry streams can be pumped with less energy and virtually no wear loss.

Concrete Industry

The major problems in making and handling concrete mixes are flow and clean-up. UHMW-PE liners can make your concrete mixes flow easily out of the truck, down the chute and into the form. Additionally, UHMW liners make concrete-handling equipment easy to clean up. No chipping or scraping with UHMW-PE. The mix washes off easily even when it sets up.

Size

uhwmpe sheets

cut to size sheets

CNC machined uhmwpe profiles

maximum length can be 6000mm

maximum width can be 2000mm

thickness can be from 6-250mm

Applications

Applications: Chain Guides, V-Roller Sleeves, Chute Liners, Discharge Gates, Chain Idlers, Chain Sprockets, Distributors, Fifth-Wheel Liners, Chain Wear Plates, Rollers, Gates, Yoke Wear Plates, Return Roller Sleeves, Belt Guides, Guides, Coupled Wear Plates

Applications: Bucket Conveyors, Conveyor Belt Rollers, Filter Scrapers, Rope Guides, Shaker Screen Guides, Chain Guides, Belt Scrapers, Filter Wipers, Rope Pulleys, Filter Guide Shoes, Chain Wear Plates, Belt Wiper Blades, Idler Pulleys, Filter Liners, Wear Bars & Plates, Chain Sprockets, Filter Plates, Idler Rollers, Shaker Screen Bar, Wear Guides

Applications: Belt Guide Rollers, Loader Liners, Chain Guides, Wiper Blades, Belt Idlers & Pulleys, Mixer Paddles, Conveyor Flights, Seals & Bearings, Flow Guides, Star & Bogey Wheels, Bushings & Bearings, Chain-Tensioning Blocks, Chutes & Hoppers, Chain Wear Plates, Sprockets

Applications: Bucket Liners, Bulk Conveyor Rollers, Wiper Blades, Chain Sprockets, Truck Liners, Hopper Liners, Scraper Blades, Conveyor Flights, Trailer Liners, Chutes, Compactor Surfaces, Drag Line Bucket Liners, Bin Liners, Sluices, Chain Wear Plate, Guide Rails

Applications: Guide Belt Scrapers, Chain Wear Plates, Guides & Skirt Boards, Belt Rollers, Scrapers & Wipers, Liners & Plates, Idlers & Pulleys, Conveyor Bucket Liners, Impact Pads & Bumpers, Sprockets, Agitators, Shoes & Tracks

Applications: Bearing Blocks & Seals, Conveyor Guides, Mixer Liners, Bearing Shields, Bottle Plates, Belt Wipers, Chute Liners, Dough Bins, Mixer Paddles, Bottle Fillers, Bottle Re-Setter, Worm Screws, Cable & Chain Guides, Conveyor Rollers, Overhead Conveyor Wheels, Bottle Labeler, Bumper Blocks, Guards & Guides, Chain Wear Plates, Filter Press Plates, Tabletop Guides, Bottle Cappers, Rollers, Corner Plates

Applications: Air Conveyor Pipes, Bumper Blocks, Chain Wear Plates, Conveyor Guides, Glue Sealer Surfaces, Bearings, Cam Guides, Chute Linings, Conveyor Rollers, Hopper Linings, Bearing Blocks, Chain Covers, Chutes, Feed Screws, Guide Plates & Rails, Bearing Seals, Chain Guides, Conveyor Belt Wipers, Feeder Arm Tips, Rollers

Applications: Valve Plugs & Seats, Pump Impellers, Pipe Fittings, Mixer Liners, Conveyor Augers, Valve Liners, Filter Plates, Tubing, Mixer Paddles, Flanges & Gaskets, Pump Housings, Filter Frames, Mixer Impellers, Doctor Blades, Level Indicator Floats, Gear Pump Gears, Filter Wiper Blades, Mixer Baffles, Feeder Chutes, Centrifuge Liners

Applications: Log Conveyor Lines, Chip Conveyor Liners, Chip Conveyor Flights, Guide Rollers, Bark Conveyor Liners, Chip & Bark Hoppers, Bumper Blocks, Pulp Paddles, Suction Box Covers & Liners, Wood Chip Hoppers, Trimmer Sticks, Chain Guides, Roller Bearings, Saw Guides, Conveyor Flights, Chutes, Doctor Blades, Idlers, Drag Flights, Sprockets

Applications: Belt Conveyor Rollers, Conveyor Belt Scrapers, Bearings & Bushings, Filter Wipes, Chain Wear Plates, Conveyor Guide, Filter Guide Shoes, Froth Cell Liners, Shaft Protectors, Guides & Skirt Boards, Bucket Liners, Rail-Car Couplers, Belt Scrapers, Impact Pads, Hydraulic Seals, Filter Plates, Floats, Diffusers, Bin Liners, Wiper Rollers, Chute Liners, Wear Plates, Chain Guides, Chain Tensioning Blocks, Wear Bars, Scrappers, Screen Bars & Guides, Slurry Bars & Guides, Picking Belt Rollers, Idler Sleeves, Gate Guides, Hopper Gates, Guide Strips, Wiper Blades, Conveyor Wheels, Exhaust Nozzles, Flume Liners, Launder Lines, Scrappers Bearings, Rope Guides & Pulleys

Applications: Wiper Blades & Scrapers, Chain Wear Plates, Bunker Linings, Chain Sprockets, Chain & Wear Guides, Wear Bars & Plates, Conveyor & Idler Rollers, Rope Guides & Pulleys.

Navigation

Mob.: +86 131 7333 7240

Phone: +86 534 5222 377

Fax: +86 534 7074 626

E-mail: [email protected]

Sype: sdxxhg518

WhatsApp: +86 131 7333 7240

Address: Liaohe Road, Ningjin Industry Zone, Dezhou City, Shandong, China

Follow Us